Global Energy Metals set for first drilling at Nevada project in search for 'critical battery materials'

|

|

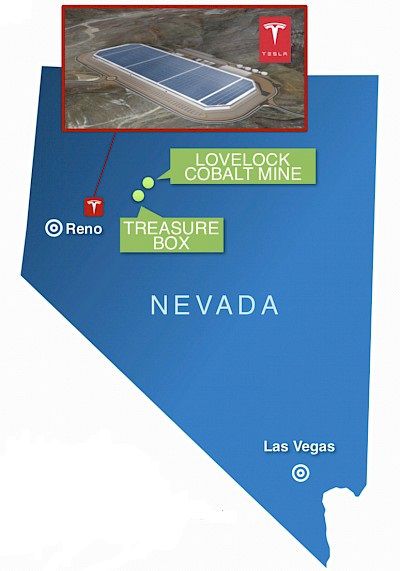

The Lovelock and Treasure Box project sites are located around 150 km east of Tesla's Gigafactory 1 in Sparks, Nevada. Image: GEM

|

Battery metals investor and developer Global Energy Metals (GEM) is preparing to start its first drilling programme at its "highly prospective” Lovelock project, in Nevada, to unearth "critical battery materials".

GEM said studies had shown the Lovelock cobalt-nickel-copper project – believed to have seen no mining activity for "well over a century” – has strong potential for new, high-grade discoveries.

Project development manager Timothy Strong said GEM has appointed the Montana-based O’Keefe Drilling Company to complete up to 1,000 metres of reverse circulation drilling at GEM’s majority-owned project.

GEM’s announcement came just days after the company announced an agreement with the American Battery Metals Corporation (ABMC), to collaborate in developing new processes to produce battery cathode grade nickel and cobalt metal sulfates.

ABMC is a lithium-ion battery recycling technology and advanced battery metals extraction company, which is the process of changing its name to the American Battery Technology Company.

According to ABMC, the majority of brine and surface sedimentary deposits in Nevada are considered "unconventional”, as their concentrations of lithium and the mechanisms by which the lithium is deposited within these host sites are "very different than at established commercial scale lithium product manufacturing sites”.

Applying existing conventional process flowsheet technologies to these resources would have resulted in extraction and conversion processes that "were not economically competitive in the current market”, ABMC said.

However, ABMC said proprietary extraction processes it is developing are based on "first-principles physics, specifically targeted at these types of lithium bearing resources, rather than adopting existing conventional processes”.

Related article in our archive:

GEM said studies had shown the Lovelock cobalt-nickel-copper project – believed to have seen no mining activity for "well over a century” – has strong potential for new, high-grade discoveries.

Project development manager Timothy Strong said GEM has appointed the Montana-based O’Keefe Drilling Company to complete up to 1,000 metres of reverse circulation drilling at GEM’s majority-owned project.

GEM’s announcement came just days after the company announced an agreement with the American Battery Metals Corporation (ABMC), to collaborate in developing new processes to produce battery cathode grade nickel and cobalt metal sulfates.

Extraction process

ABMC is a lithium-ion battery recycling technology and advanced battery metals extraction company, which is the process of changing its name to the American Battery Technology Company.

According to ABMC, the majority of brine and surface sedimentary deposits in Nevada are considered "unconventional”, as their concentrations of lithium and the mechanisms by which the lithium is deposited within these host sites are "very different than at established commercial scale lithium product manufacturing sites”.

Applying existing conventional process flowsheet technologies to these resources would have resulted in extraction and conversion processes that "were not economically competitive in the current market”, ABMC said.

However, ABMC said proprietary extraction processes it is developing are based on "first-principles physics, specifically targeted at these types of lithium bearing resources, rather than adopting existing conventional processes”.

Related article in our archive:

Curated selection

- Casinos Not On Gamstop

- Nuovi Casino 2025

- Casinos Not On Gamstop

- Casino Sites Not On Gamstop UK

- Casino Online

- Online Casinos

- Best Online Casino Canada

- Non Gamstop Casinos

- Sports Betting Sites Not On Gamstop

- Slots Not On Gamstop

- Casinos Not On Gamstop

- UK Online Casinos Not On Gamstop

- Casino Sites Not On Gamstop

- Casino Not On Gamstop

- Casino Not On Gamstop

- UK Casino Not On Gamstop

- Best Casino Sites UK Reviewed

- Meilleur Casino En Ligne France

- Casinos Not On Gamstop

- Betting Sites UK

- List Of Best Online Casinos

- Migliori Siti Casino Non Aams

- Siti Casino Non Aams

- Non Gamstop Casino Sites UK

- Crypto Casino

- Sites De Paris Sportifs Belgique

- I Migliori Casino Non Aams

- Casino En Ligne

- ブックメーカー

- Meilleurs Casino En Ligne

- Casino En Ligne

- Casino En Ligne Retrait Immediat

- Casino En Ligne France

- Siti Slot Non Aams

- Miglior Casino Online Non Aams

- Meilleur Casino En Ligne

- Casino En Ligne France Fiable

- Nouveau Casino En Ligne

- казино онлайн україна

- Lista Casino Non Aams